Rotary valves: The right one for every application!

Rotary valves are important components in conveying technology for feeding, discharging or dosing fine-grained and dusty products or granulates. In order to relieve the bulk material of the silo pressure, rotary valves are often installed under silos. Downstream elements in the conveyor chain, such as tube chain or trough chain conveyors or screw conveyors, are relieved and the entire system runs more consistently with less maintenance.

Our portfolio of rotary valves covers every need

Neue JÄGER Maschinenbau is a manufacturer specialising in the development and sale of rotary valves. Every customer requirement can be solved! The highest quality requirements are already applied during product development and design. Our rotary valves are used as top products for the controlled discharge and dosing of powdery and granular materials. And this worldwide! The main areas of application are in the food industry as well as in the areas of plastics production and processing, the pharmaceutical and chemical industries and the mineral processing industry.

Whether pneumatic rotary valves with rotation monitoring, over- or underpressure-tight versions or special designs to customer specifications: we develop and manufacture every rotary valve to the highest technical standard. Please do not hesitate to contact us!

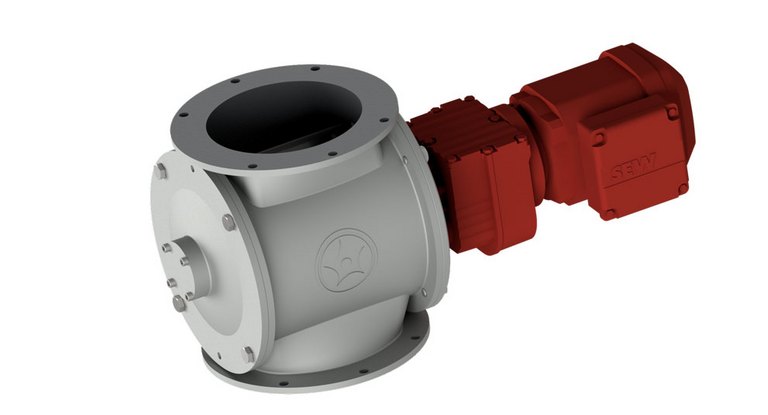

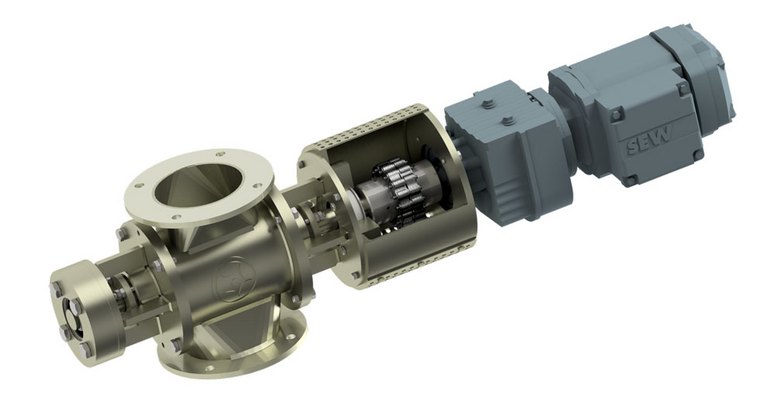

Rotary Valve ZRS COMPACT

Compact rotary valve with directly flanged gear motor available in 10 different sizes. Also available as ATEX device and autonomous protection system for gas and dust explosive atmospheres according to RL2014/34/EU.

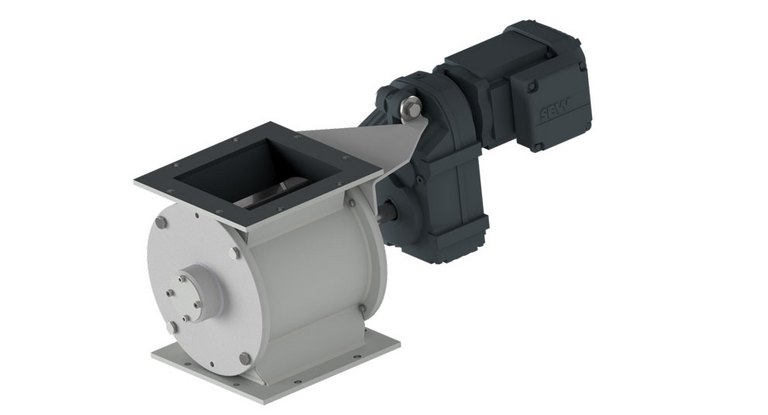

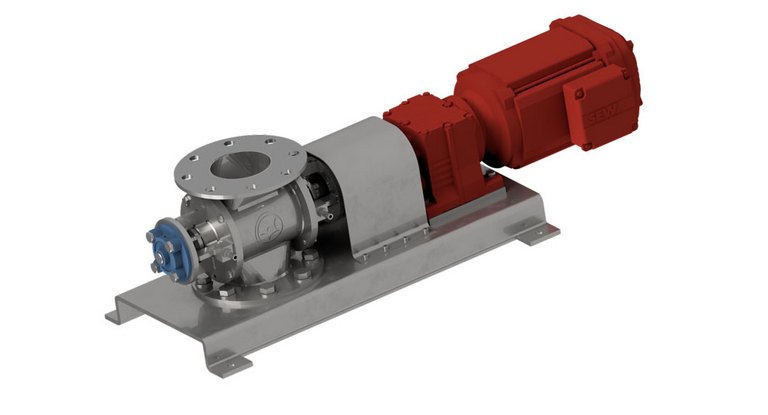

Rotary Valve ZRS STANDARD

Rotary valve with free shaft end for versions with motor lantern and coupling or torque arm for slip-on gearmotors. All variants with round or square flanges. Flange connections according to EN1092-1:2001 with hole patterns according to PN6 or PN10.

Rotary Valve ZRS HEAVYDUTY

Rotary Valve for applications under difficult conditions with external bearing and packing gland, with purging or sealing gas feed also for aggressive or wearing pumped media. Also available as ATEX rotary valve according to RL2014/34/EU.

Rotary Valve ZRS EASYCLEAN

Cleaning sluice with rotor extraction device for fast product change. Also available as ATEX device or autonomous protection system with screwed bearing cover or quick clamps from AMF us safety switch.

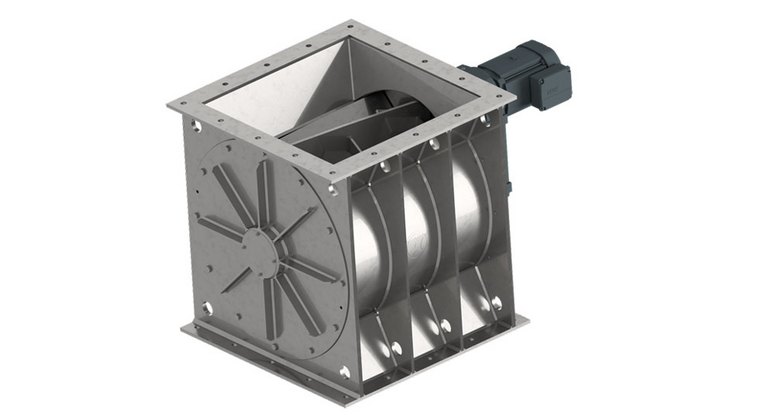

Rotary Valve ZRS XL

Rotary valves for large conveying capacities in extended design. Particularly well suited also for large-volume conveying media such as rock wool. The rotary valves are also available with inclined web plates for a continuous conveying flow.

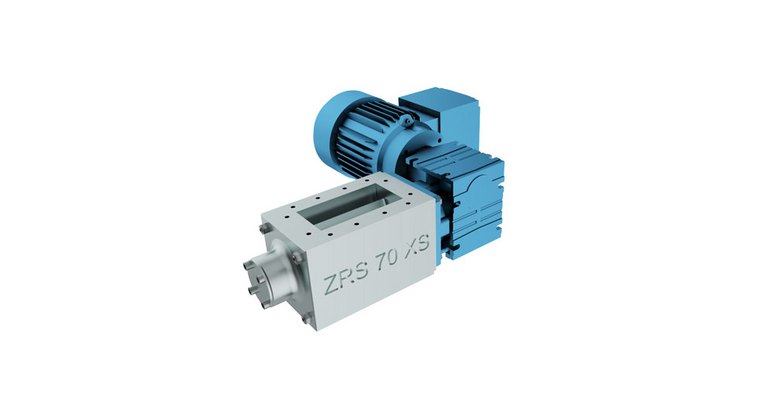

Rotary Valve ZRS 70 XS

The ZRS 70 XS is designed for use as a metering or sampling rotary valve in the chemical and pharmaceutical industries. The ZRS 70 XS rotary valve is also available in plastic.

Medium pressure rotary valve

Medium pressure rotary valves for pressure differences up to 1.5 bar. Rotary valves with 10 or 12 chambers and sluices in many different housing designs. With directly flanged drive or motor lantern, coupling or torque arm.

High-pressure rotary valves

Rotary valves for differential pressure up to 3.5 bar. Rotary valves with up to 14 chambers, suitable for pneumatic conveying systems, also with AGS feed shoe. AGS on request free of dead space and polished with surface roughness < 1µm.

High temperature rotary valve

Rotary valves for highest temperatures with ceramic deep groove ball bearings made of silicon nitride - especially suitable for use in pyrolysis plants. Can be used for temperatures up to over 750 °C.

FDA rotary valves

FDA and EC 1935/2004 compliant rotary valves are used in the food and pharmaceutical industries. Also available as ATEX rotary valves with polished internal parts, rounded chamber plates and CIP-capable on request.

Therefore rotary valves from Neue JÄGER Maschinenbau

Our construction kit includes a wide and varied range of variants and combination options in different designs and materials, with different sealing systems and drive concepts:

- Directly flange-mounted geared motor

- With and without torque support

- Motor lantern

- Base plate

- Chain drive

- Large variety of cellular wheels for specific applications

In addition to a wide range of modern rotary valves, which are currently manufactured in sizes 100 to 1000, an EC type examination certificate from DEKRA EXAM (notified body no. 0158) in accordance with Directive 2014/34/EU of the EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014 is also available for our construction kit.

Each New JÄGER Rotary Valve can be used as a machine in the sense of the Machinery Directive 2006/42/EC and as a type-tested device of Category I or as an autonomous protective system for explosion decoupling. Category 1D, 2D or 3D devices are available for use in zones 20, 21 or 22.

Neue JÄGER thus offers all plant manufacturers or operators of plants a complete range of ATEX rotary valves for the implementation of EU Directive 2014/34/EU or ATEX 137. Each individual rotary valve is pressure shock resistant up to 25 bar and ignition proof up to 10 bar.

Contact your partner for rotary valves

If you have any application-specific questions about our range of rotary valves, we will of course be happy to help. Contact us!