Your rotary valve manufacturer since 1985

Rotary valves of Neue JÄGER: our product portfolio

Rotary Valves for Pellets, Powders & More: Select Your Rotary Valve Based on Applications and Use Cases

Rotary valves are indispensable in modern bulk material handling. They perform a wide variety of tasks for dosing, feeding, or discharging bulk materials. The conveyed medium can have a wide range of properties that the rotary valve must manage reliably.

Therefore, simply select your rotary valve based on your application: we have the right rotary valve with various chamber volumes for bulk materials, granules, plastics, pellets, and much more. As product developers, we also offer customized solutions. Simply contact us to discuss all the details personally.

Rotary valves for applications up to 1200°C

ATEX rotary valves according to EU Directive 2014/34/EU

Neue JÄGER offers a wide range of rotary valves according to Directive 2014/34/EU for potentially explosive atmospheres in Zones 20, 21, and 22 and is one of the leading manufacturers worldwide whose rotary valves can also be used for gases atmospheres in Zone 1 or 2. Of course, our rotary valves are also available without ATEX marking according to the Machinery Directive in the following versions:

ZRS COMPACT with a direct mounted gear drive ->

ZRS STANDARD with free shaft end ->

ZRS HEAVYDUTY with outboard bearings ->

FDA Rotary valves

Medium- and High-pressure rotary valves

Medium-pressure rotary valves of type MDS for pressures up to

1.5 bar and high-pressure rotary valves of the HDS series for

pressures up to 3.5 bar typically have a larger number of

chambers. The resulting increase in the sealing surfaces

between the rotor and the valve tube allows for bridging even

larger pressure differentials between the inlet and outlet of the

rotary valve, up to 3.5 bar.

Learn more about the diverse possibilities.

Medium-pressure rotary valves MDS ->

High-pressure rotary valves HDS ->

EASYCLEAN rotary valves with rotor extraction devices

Rotary valves of the EASYCLEAN series feature a rotor extraction device for easy disassembly of rotor

and housing. The rotor is pulled out of the housing along with the bearing cover using the extraction

device. The housing and rotor are then easily accessible and can be cleaned. The bearing cover can

be easily opened using hex bolts or quick-release fasteners from AMF.

The ZRS EASYCLEAN rotary valve is also available as an Autonomous Protection System with safety

switches for the opening process.

Rotary valves series XL

XL series rotary valves with rotor diameters up to 1250 mm and an extended housing for high flow

rates. XL series rotary valves can also be supplied as equipment compliant with EU ATEX Directive

2014/34/EU.

XL series rotary valves are typically built with external ball or slide bearings.

Cleaning flaps in the inlet and outlet, or in the valve tube, are available, along with many other

options.

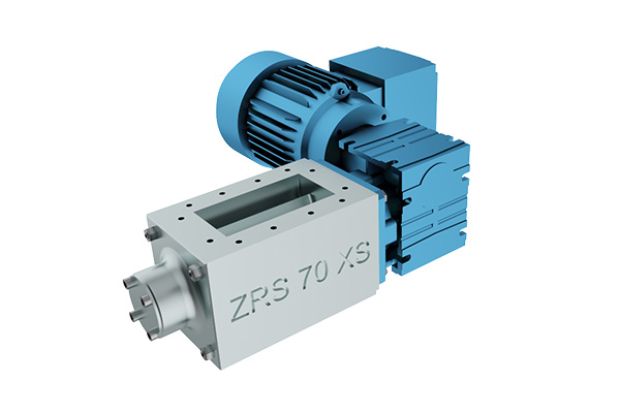

Rotary valves of the XS series for laboratory and dosing applications

The ZRS 70 XS rotary valve with directly flanged geared motor is used for dosing, conveying, and

discharging small quantities of bulk materials.

For use in the chemical and pharmaceutical industries for dosing, discharging, or sampling, all

product-contacting components can be made of plastic, aluminum, or stainless steel. The rotary

valve can be operated via a frequency converter for dosing.

Designed according to Machinery Directive 2006/42/EC.

Your partner in machine and plant construction

Neue JÄGER Maschinenbau & You:

Contact your rotary valve manufacturer

Whatever your request – as a rotary valve manufacturer with many years of experience, we are sure to find a tailor-made solution for your application. Please feel free to contact us, we look forward to hearing from you.