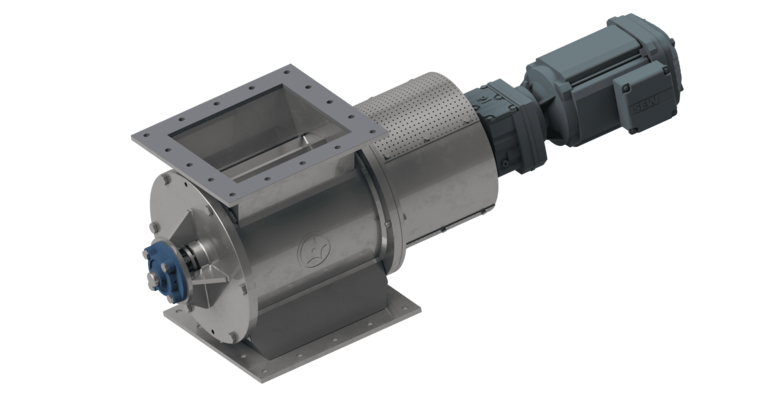

High pressure rotary valves are used for dosing, conveying and discharging bulk materials or other granulates and powders. The high pressure rotary valves are suitable for pressure differences up to 3.5 bar and are also used in pneumatic conveying systems. Design also according to Machinery Directive 2006/42/EC or ATEX Directive 2014/34/EU.

Type

- Drive via directly flange-mounted gear drive or with free shaft end

- With motor lantern, elastic coupling, torque support or base plate

- With rotor extracting device as ZRS EASYCLEAN

- Seal via radial shaft sealing rings or gland seal packing

- Housing as cast or welded construction

- With round or angular inlet and outlet

- Cellular impellers with up to 14 chambers

- Surface primed, painted, blasted, pickled or chemically nickel-plated

- Structurally safe

- Pressure shock resistant up to 25 bar according to RL2014/34/EU

- Pressure shock resistant and ignition proof up to 10 bar according to RL2014/34/EU